上海鼎徵仪器仪表设备有限公司

蒸汽喷射试验机满足测试规范汽车厂家:宝马、奔驰、通用、大众、福特、沃尔沃等规范(AA-0136、DIN

55662、ISO16925,DBL

7381,GM9531P、PV1503、VOLVO

STD 423-0015,VOLVO

VCS

1029 54719、FLTM

BO

160-04、MS210-07,PSA

D23 5376,Renault D25 2018/-A-2001

,GMW16745-2012方法B,TPJLR-52.561-2009)

1 Scope 上海鼎徵仪器仪表设备有限公司

This International Standard specifies a test method

for the assessment of the resistance of coatings to

pressure

water-jetting. The test method simulates the effects pressure water-jetting has

on a coating.

5

Apparatus and materials

Ordinary laboratory apparatus, together with the

following:

5.1

Pressure water-jet, consisting of a high-pressure pump and a nozzle.

A

high-pressure pump conveys the water from a storage bin. To avoid influences

from variations in

pressure, it is necessary that the pressure and the

volumetric flow rate be adjustable at the nozzle

described below.

The water temperature shall be adjustable to ± 2

°C.

The

temperature shall be adjusted in accordance with Annex A. Necessary safety devices on the pressure

side of

the unit, as e.g. pressure relief valve and by-pass valve, shall exist. If the

jetting is unsteady, a flow

calming section may be installed in front of the

nozzle. A pulsation of the water jet at the opening of the

pump is

inadmissible. In order to reach a reproducible result, the nozzle shall be

solidly mechanically

fixed

and the test specimen shall be secured against slipping. For the adjustment of

the volumetric flow

rate, a

nozzle with a jet angle of 25° and a volumetric flow rate of 6 l/min at 2 MPa

(20 bar) is required

(see

Annex

A).

The

following technical data should be attainable:

— volumetric flow rate: 8 l/min to 14 l/min

—

pressure: 4 MPa (40 bar) to 13 MPa (130 bar)

— temperature: 20 °C to 80 °C

—

jetting time: 10 s to 300 s

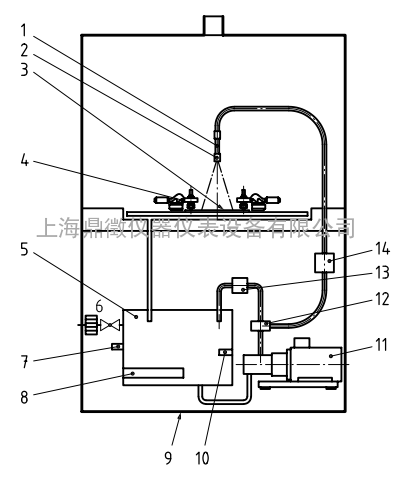

Figure

1 shows

the schematic construction of a pressure water-jet apparatus which is specially

built for these

tests.

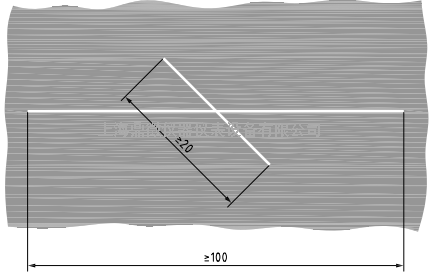

8.1

Introducing the cut or the scribe 上海鼎徵仪器仪表设备有限公司

Make sure that the test specimen is securely

fastened when introducing the cut or the scribe.

Introduce both of the cuts or scribes vertically

through the coating into the substrate using the cutting

or

scribing tool, as shown in Figure 2. The depth of the cut or scribe into the substrate

should be as

minimal

as possible. The length of the first cut or scribe shall be at least 100 mm, if

the geometry of the

part

allows that. At an angle, introduce a second cut or scribe with a minimum length

of 20 mm. The

cuts or

scribes shall be introduced straight-line at an angle of approximately 30°. An

automatic cutting

or

scribing device may be used. Residues of the coating shall be removed from the

cut or scribe.

NOTE The

depth of the cut or scribe into the substrate influences the result.

The

cutting or scribing tools should be checked regularly and replaced if

necessary.

Figure 2 — Introducing the cuts or scribes (St Andrew’s

cross)

8.2

Testing

After

inserting the test specimen into the apparatus (e.g. using a spacer block),

calibrate the space

between

test specimen and nozzle.

Operate the pressure water-jetting apparatus at

room temperature.

Three

test methods (A, B, or C – see Table 1) are preferred as well as three possible scribing

tools (C, L, or

S – see

5.3). The test method to be applied, the scribing or

cutting tool to be used, and the water pressure

shall be agreed.

Table 1

— Test methods 上海鼎徵仪器仪表设备有限公司

|

Test

method

|

Water

Temperature

℃

|

Impact

angle

|

Space

between nozzle and sample (mm)

|

Flow

rate

(L/min)

|

Duration

of

jetting

|

|

A

|

60±2

|

90±2

|

100±1

|

11.3±0.2

|

30±1

|

|

B

|

60±2

|

90±2

|

100±1

|

11.3±0.2

|

60±1

|

|

C

|

60±2

|

90±2

|

100±1

|

11.3±0.2

|

60±1

|

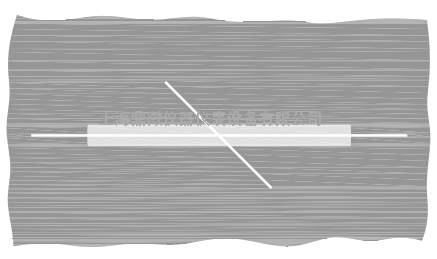

For

jetting, deionized water should be used.

When using automatic and manual devices, fasten the

test specimen so that the water jet impacts as

shown in Figure 3. The jet impacts in the middle above the point of

intersection onto the longer one of both cuts/scribes.

Figure

3 — Jetting area

After

jetting, the length and the width of the impact are measured. See

Figure

A.1.

The mean

length of the impact shall be (73 ± 5) mm and the mean width (8 ± 1) mm on

average.

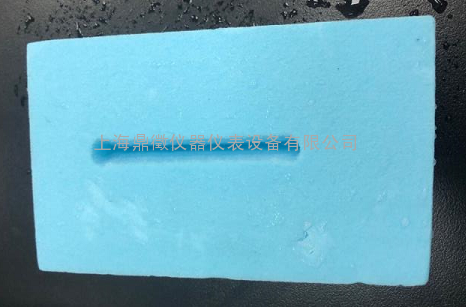

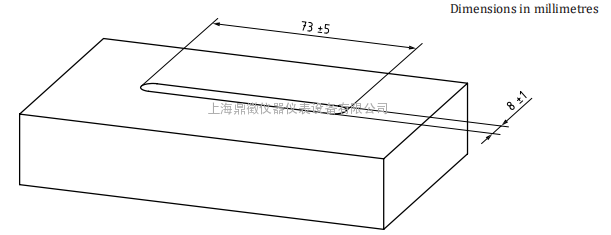

Figure

A.1 — Measures of the washed-out areas in the polystyrene rigid plastic

foam